金湖通奧機(jī)械有限公司

www.ggjmjx.com/company/d4450268/

掃一掃,手機(jī)訪問(wèn)

金湖通奧機(jī)械有限公司

供應(yīng)(通奧)電加熱定型機(jī) 價(jià)格及報(bào)價(jià)

價(jià)格:¥150008.00

價(jià)格:¥79080.80

| 品類 | 倍捻機(jī) | 品牌 | TY |

|---|---|---|---|

| 規(guī)格 | 0.5/2.8T | 型號(hào) | PTZXK&mdash |

| 氣流紡紗機(jī) |

air current spinning machine

i take charge in recent years through with the overseas enterprise cooperation, in finalizes to steam in box's foundation, promotes the yarn steaming pot/to boil the gauze pot/to boil the loom product, the product quality achieves the world same profession advanced level.

boils the loom to be suitable finalizes in the corrugation cloth, the rain umbrella cloth coloration, the printed cloth coloration, the lace, the window blind, the towel dye printing finalizes, the carding, the cashmere sweater dye printing stereotypia and so on.

i take charge of the yarn vacuum which produces for the wet yarn steaming machine to be possible to the yarn to carry on the heat setting. for the wet treatment, the even seepage, the low temperature indirect -like yarn steaming increases the cotton yarn weight to reach 1.7%-…3%, increases the wool yarn weight to reach 2.4%--4%. the gauze pot/boils the gauze pot to be suitable the tailoring line, the pure silk, the filament, the cotton yarn, t

the ordering specification model with finalizes to steam the box model to be the same. may provide each kind of product the basic craft and the parameter, simultaneously provides corresponding local the factory test specimen, to examine merchandise and so on services. the technical parameter is as follows:

1st, increases the humidity (weight).

2nd, the improvement gauze's characteristic increases the gauze the intensity, the elastic good rich feeling non-static electricity load and so on.

3rd, reduced textile fiber fly.

4th, even humidity distributed yarn steamin

yarn setting craft goal

1st, reels thread the after-fixing number of twists

2nd, but actually tube after-fixing number of twists

3rd, not entangles the gauze phenomenon

4th, the even number of twists gauze finalizes <dnt> the </dnt> yarn gives wet craft goal

1st, stability

2nd, relaxation

3rd, contraction

4th, shrinks the material in advance

may finalize to give wet stock

1st, 100% cotton and kapok

2nd, 100% wool

3rd, 100% viscose fiber

4th, blend fiber material

5th, natural textile fiber

6th, synthetic fiber

7th, blend fiber material

8th, synthetic fiber, polyester fiber, chemical fiber, acrylic fibers and so on

9th, textured yarn

10th, twists the filament high

11th, wooltop and short fiber in rolling

12th, each kind of revertex bobbin or cardboard bobbin

13th, can use the low price the cardboard tube to roll

processing temperature

1st, 50~80℃

the biggest vacuum reaches 90% (located at sea level 50 millibars) the processing temperature

2nd, 65~110℃

the biggest vacuum reaches 90% (located at sea level 100 millibars) the processing temperature

3rd, >100℃

the biggest vacuum reaches 90% (located at sea level 100 millibars) to reach 95% (special vacuum equipment)

processing pressure

-0.1mpa~0

process time 30~60 minute processing pressures

-0.1mpa~ 0.1mpa

process time 10~90 minute processing pressures

-0.1mpa~ 0.4mpa

process time 30~180 minutes (yarn) 20~40 minutes (wooltop and short fiber).

attention: has any question please with my company handset 15195513387

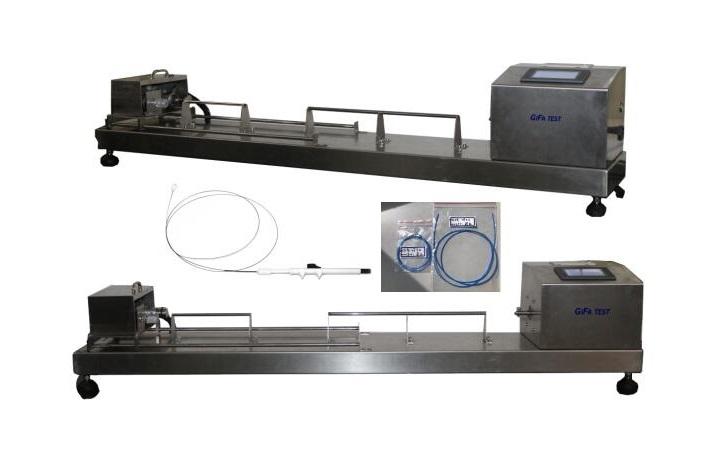

JFY-265S型醫(yī)用取石網(wǎng)籃扭控傳遞性能測(cè)試儀

價(jià)格:¥98000.00

JFY-265型手動(dòng)式取石網(wǎng)籃扭控傳遞性能測(cè)試儀

價(jià)格:¥8800.00