佛山市順德區德博仕機械設備有限公司

www.ggjmjx.com/company/d4451704/

掃一掃,手機訪問

佛山市順德區德博仕機械設備有限公司

| 品類 | 定型機 | 品牌 | 德博仕 |

|---|---|---|---|

| 規格 | 13盤,14盤,15盤,16盤,17盤 | 型號 | DBS-PZJ |

定型機助劑施加系統 setting machine auxiliary feeding system

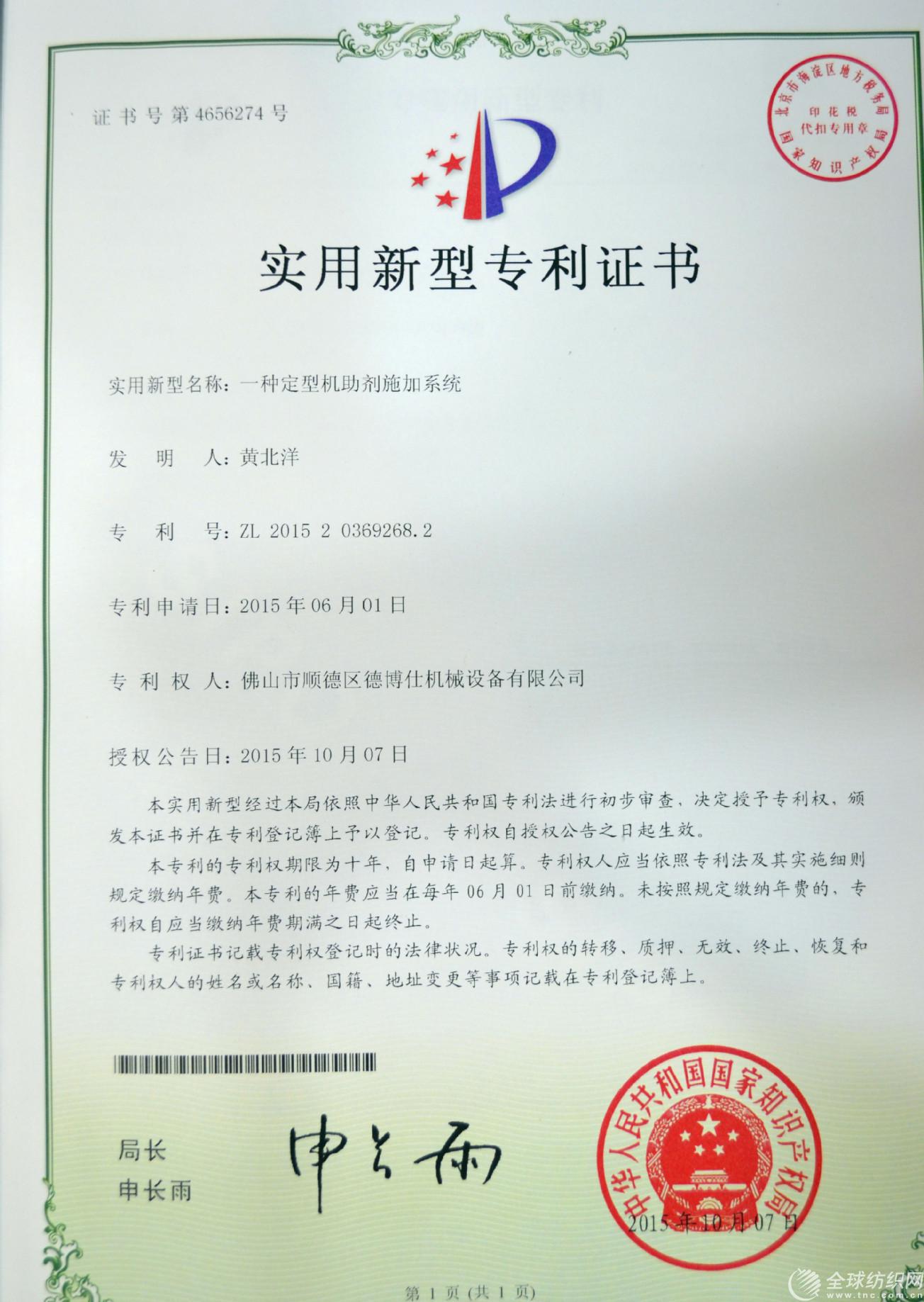

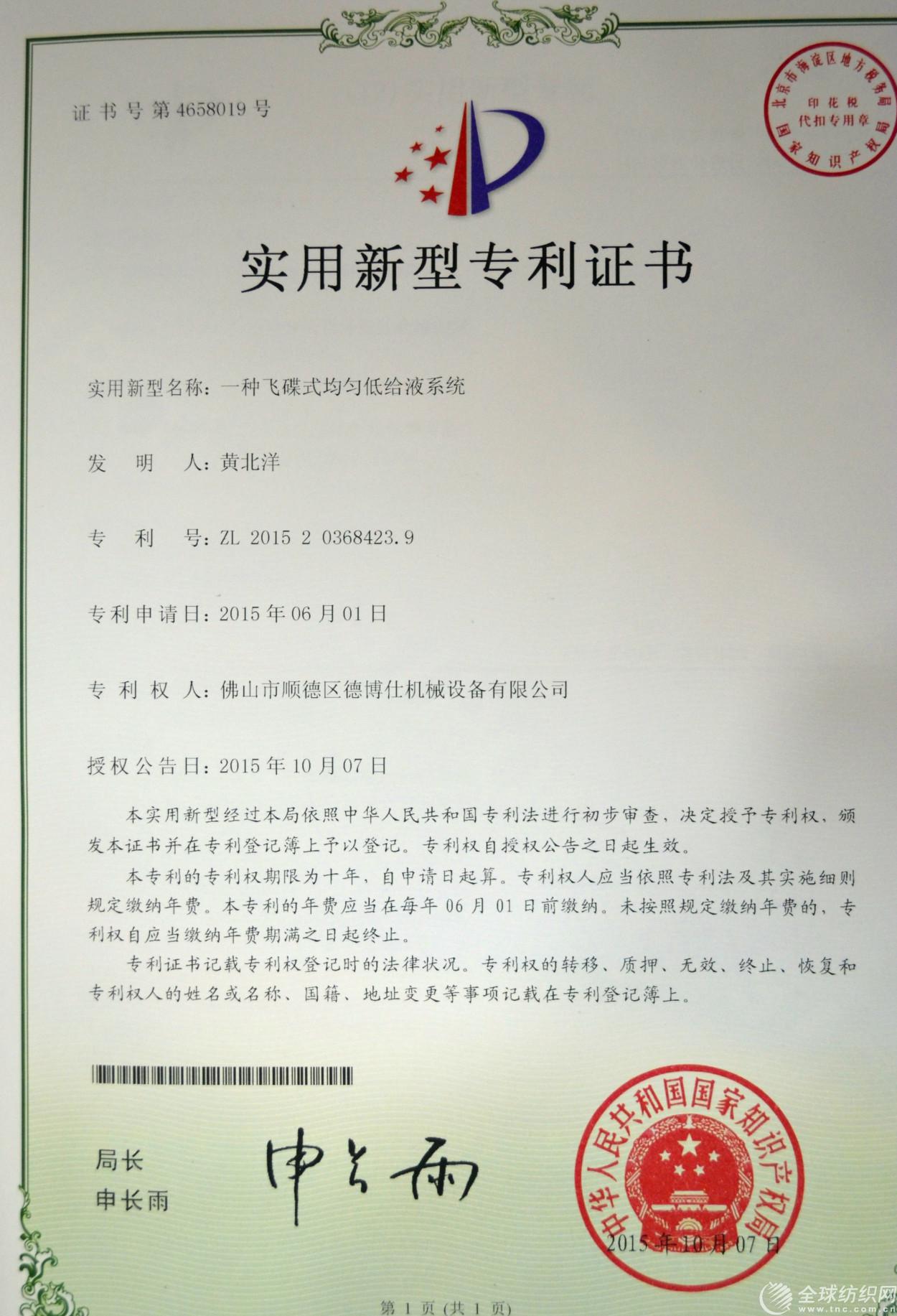

專利號:zl 2015 2 0368423.9 patent no.:zl 2015 2 0368423.9

zl 2015 2 0369268.2 zl 2015 2 0369268.2

zl 2015 3 0173867.2 zl 2015 3 0173867.2

一.概述: summary

定型機助劑施加系統。助劑施加方法是將助劑液體在高速旋轉“碟片”受到強力的離心力作用形成水膜,并被“碟片”上的離心線切割成微米級線性水霧高速強力噴射到布料表層,再經過小軋車均勻滲透于布料纖維層的技術,達到快速滲透于布料纖維層的目的。

the setting machine auxiliary feeding system:the auxiliary feeding method is to make the auxiliary liquid water film under the strong centrifugal force formed by high-speed rotating disc and cut by the disc into micron linear mist that sprays to the fabric surface at a high speed and penetrates into the fibrous coat of the cloth evenly by rolling cart quickly.

一. 設備使用范圍以及優點 application scope and advantages

(一)、目前定型機添加助劑工藝流程:平幅進布(帶液率約20%)→紅外擴幅對中→漿槽添加助劑→二輥軋車(帶液率約75%)→下超喂→螺紋擴幅→上超喂→剝邊→探邊→上針→漿邊→拉幅熱定形→冷風冷卻→脫針→切吸邊→冷水輥冷卻→擺式落布或卷裝落布。

process flow of auxiliary feeding of current setting machine:

open-width cloth feeding (with about 20% of liquid carrying rate)→ ir width expanding centring→ auxiliary feeding from slash vat system → 2-roll rolling cart (with about 75% of liquid carrying rate) →low overfeeding→ whorl width expanding→ upper overfeeding→ uncurling→ edge detecting→ purling→ edge starching → tentering and heat setting → cold wind cooling → needle freeing→ cutting & edge suctioning→ cooling by cold water roll→ pendulous cropping or rolling package

弊端分析:analysis on advantages

1、在漿槽添加助劑過程中,化料桶中的助劑一直定量不間斷輸送到漿槽,當漿槽助劑達到溢流口位置時助劑直接排放,導致助劑直接浪費。

during the auxiliary feeding from the slash vat, the chemical materical barrel keeps supplying auxiliary to the slash vat. when the auxiliary reaches the flow-off, it will be discharged directly, which leads to direct waste.

2、布料經過漿槽添加助劑之后直接到達二輥軋車時,軋車把布料攜帶的大部分水份軋出,并且倒流回漿槽。當水份倒流回漿槽時導致原有漿槽中的助劑濃度的改變(水份倒流回漿槽越多,漿槽中的助劑濃度就越底),所以在長時間生產過程中很難保證布料品質一致。(如“機尾操作師傅”經常要求“機頭操作師傅”改變助劑濃度的高底)

when the fabric reaches the 2-roll rolling cart directly after auxiliary feeding in slash vat, the rolling cart presses most water carried that returns back to the slash vat and changes the thickness of the auxiliary in the slash vat (the more returned water, the lower thickness of auxiliary in slash vat), which can not ensure the equal quality of the fabric after a long time. (for example, the operator at the end of the machine often requires the one at the head of the machine change the thickness of the auxiliary.)

3、目前所有經過二輥軋車出來后布料的“帶液率約75%”,如此大的“帶液率”經過烘干需要費很大 熱能、電力、人力、陣用機臺、并且生產效率底下。

the liquid carrying rate of the fabric rolled by the 2-roll rooling cart is about 75% that should be dried with big consumption of heat energy, power, labor and machine with low production efficiency.

(二)、定型機助劑施加系統工藝流程:平幅進布(帶液率約20%)→紅外擴幅對中→定型機助劑施加系統(帶液率約25%)→下超喂→螺紋擴幅→上超喂→剝邊→探邊→上針→漿邊→拉幅熱定形→冷風冷卻→脫針→切,吸邊→冷水輥冷卻→擺式落布或卷裝落布。

process flow of setting machine auxiliary feeding system:

open-width cloth feeding (with about 20% of liquid carrying rate)→ ir width expanding centring→setting machine auxiliary feeding system (with about 25% of liquid carrying rate)→ low overfeeding→ whorl width expanding→ upper overfeeding→ uncurling→ edge detecting→ purling→ edge starching → tentering and heat setting → cold wind cooling → needle freeing→ cutting & edge suctioning→ cooling by cold water roll→ pendulous cropping or rolling package

定型機助劑施加系統 優勢如下:

the advantages of setting machine auxiliary feeding system are as below:

1、德博仕-定型機助劑施加系統。助劑施加方法是將助劑液體在高速旋轉“碟片”受到強力的離心力作用形成水膜,并被“碟片”上的離心線切割成微米級線性水霧高速強力噴射到布料表層,再經過小軋車均勻滲透于布料纖維層的技術,達到快速滲透于布料纖維層的目的。系統配備回收槽,可回收布料幅寬外不被布料所吸的助劑,達到助劑零排放標準。

deboshi setting machine auxiliary feeding system:

the auxiliary feeding method is to make the auxiliary liquid water film under the strong centrifugal force formed by high-speed rotating disc and cut by the disc into micron linear mist that sprays to the fabric surface at a high speed and penetrates into the fibrous coat of the cloth evenly by rolling cart quickly. there is reclaim tank in the system to reclaim the non-absorbed auxiliary out of the width of the cloth to reach the goal of zero release of auxiliary.

2、助劑施加過程中,可確保全幅布料(緯向)均勻且連續施加,助劑的施加量可依需求而先行設定。在運轉過程中,系統會依定型機速度變化而自動調整,確保全程(經向)施加助劑量相等,布料品質一致。

the auxiliary feeding process ensures the even and continuous feeding of auxiliary on the whole-width cloth (laterally) with feeding quality set in accordance with the requirement. during the operation, the system will be adjusted according to the change of the speed of the setting machine to ensure the evenness of auxiliary feeding to ensure the equal quality of the whole-width cloth.

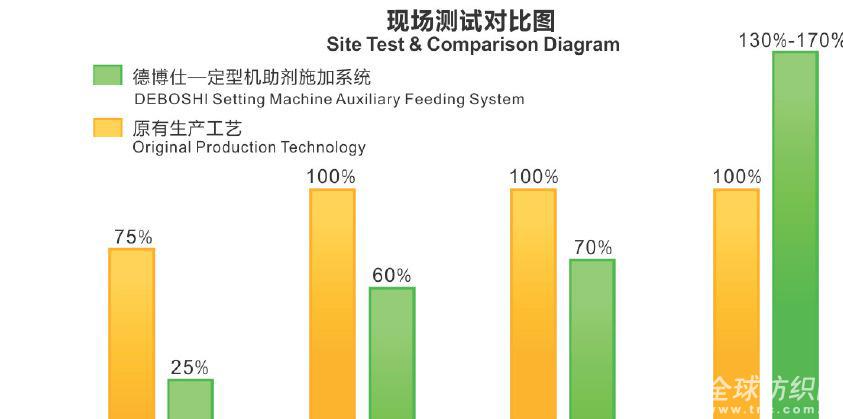

3、由德博仕-定型機助劑施加系統(帶液率約25%),**原有二輥軋車(帶液率約75%),明顯降低了約50%帶液率。在兩者相同條件下,定型機效率可提高30%-70% 、節約熱能、電力、人力約20%-50% 、節約助劑約40% 。(如下圖1)

deboshi setting machine auxiliary feeding system (with about 25% of liquid carrying rate) replaces the original 2-roll rolling cart (with about 75% of liquid carrying rate),lowering about 50% of liquid carrying rate evidently. under the same conditions, the setting machine can heighten 30% to 70% of efficiency, save 20% to 50% of heat energy, power and labor cost, and save about 40% of auxiliary.

一. 技術性能和標準配置:

technical performances & standard configures

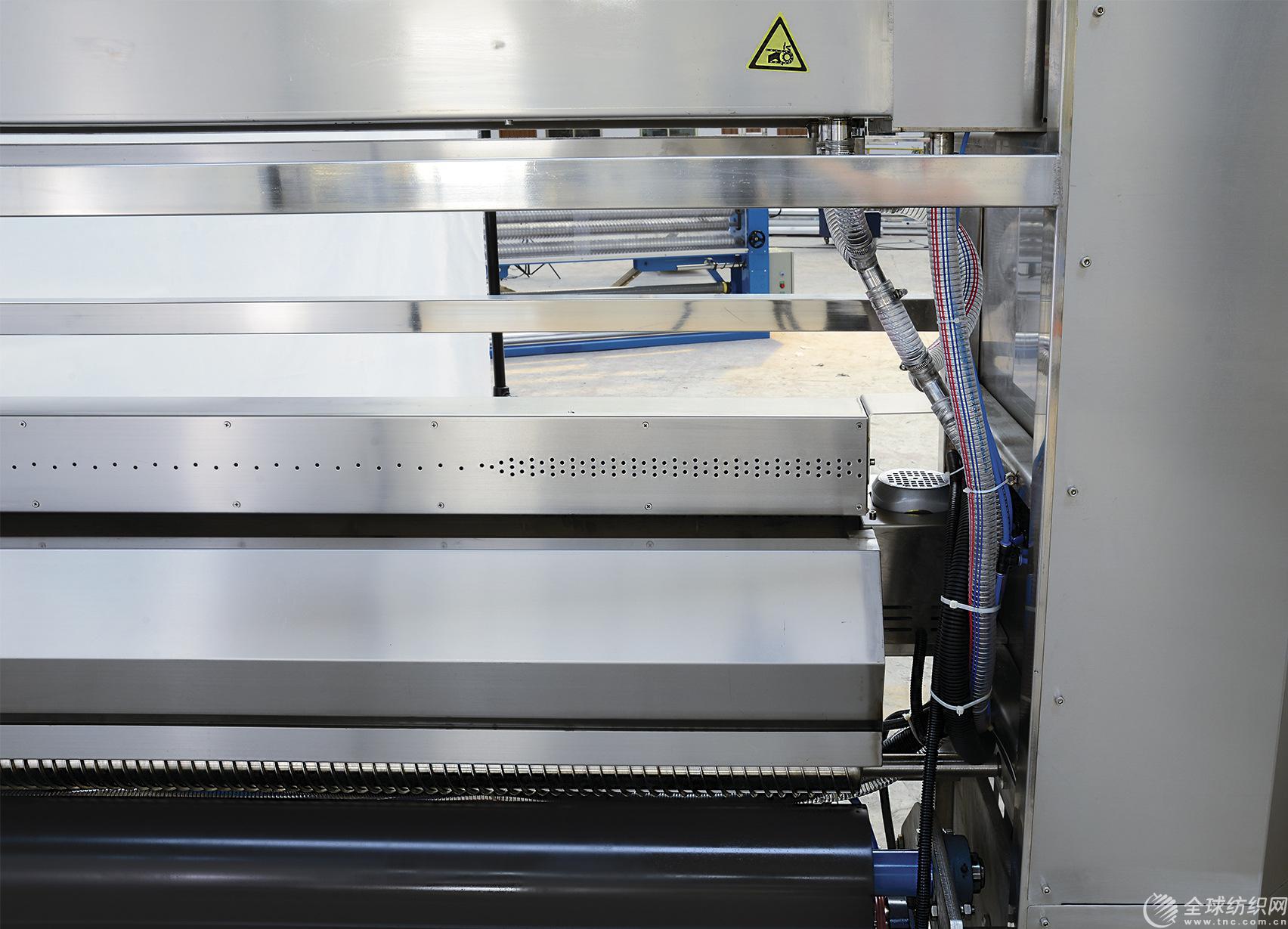

1、 整機均以優質不銹鋼304制成,專門設計特殊結構。

the whole machine with special designed structure is made of 304# stainless steel

2、 助劑施加系統采用小功率馬達、瑞士高強度耐磨平面傳動帶。

low-powder motor and high-strength abrasion-resistant flat transmission belt are used for the auxiliary adding system

3、 碟片采用進口特種工程塑料精密注塑成型。

the flying disc is made by injection moulding precisely with imported special engineering plastic

4、 供液系統采用變頻調速水泵,具有供液、回收液體過濾器裝置。

the liquid feeding system makes use of frequency control pump, with liquid feeding, recycled liquid filtering equipments

5、 電氣控制系統采用臺灣weinview人機界面、三菱可編程控制器(plc)及臺灣shihlin變頻器。

the electric control system makes use of the weinview man-machine interface from taiwan, programmable logic controller (plc) of mitsubishi and shihlin frequency transformer from taiwan

6、 進口自動測速編碼器,根據車速自動調整供液量.

the imported automatic speed encoder can adjust the liquid feeding quantity according to speed of vehicle automatically

7、 供電功率:380v / 50hz / 2.5kw。

powder of supply electricity: 380v / 50hz / 2.5kw

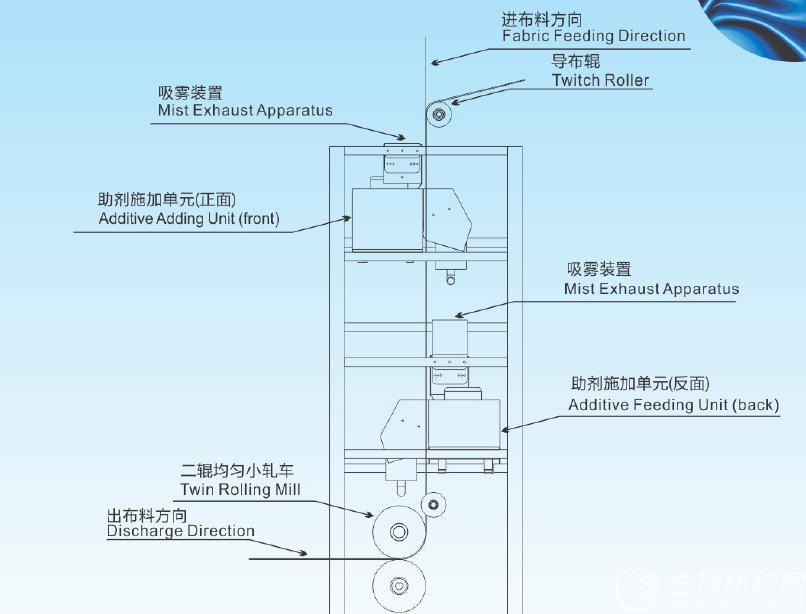

8、 設備組合單元由:助劑施加單元正反面各一套、吸霧裝置正反面各一套、二輥均勻小軋車一套、供液系統一套、控制電柜一套、防滴水液槽一套、導布輥一件、機架一臺。

the unit of the equipment combination is composed of: each one set of positive and negative sizes of auxiliary feeding units, each one set of positive and negative sizes of mist suckling devices, one set of 2-roll uniform rolling cart, one set of liquid feeding system, one set of powder control cabinet, one set of water drop-proof tank and a machine rack.

9、 當定型機停機后,助劑施加系統自動啟動反清洗功能。定型機再次開機時自動恢復正常工作。

when the setting machine stops, the auxiliary feeding system will start the back wash function automatically. and the setting machine will recuperate the normal work when it is restarted.

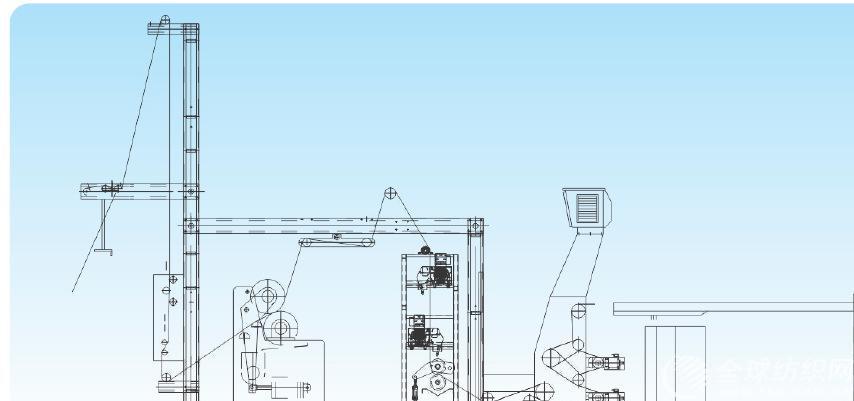

四、定型機助劑施加系統結構:(如下圖2)

structure of setting machine auxiliary adding system (as figure 2 below)

五、定型機助劑施加系統與定型機組合裝置工作流程圖:

work flow chart of setting machine auxiliary adding system & setting machine unit equipment (as figure 3 below)

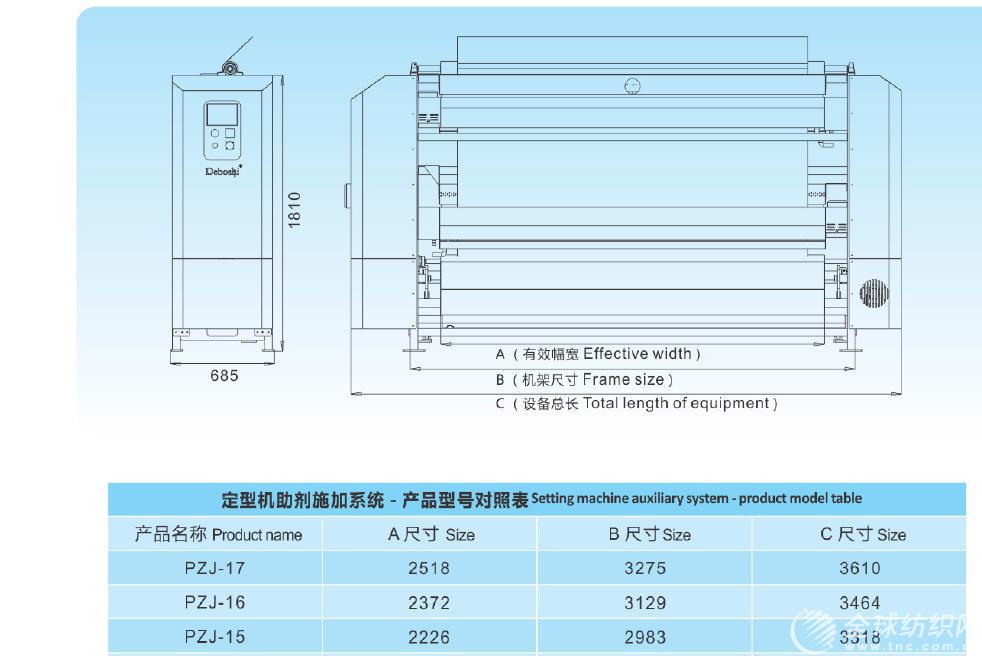

六、設備外觀尺寸 size of equipment (as figure 4 below)

國家專利證書

佛山市順德區德博仕機械設備有限公司是一家專業從事印染機械研發、生產的科技型企業 。公司坐落于交通便捷、經濟*具活力的珠三角洲,制造業重鎮-順德。

我們秉承質量是生存之本,誠信是服務之根的服務宗旨,專業生產、銷售定型機助劑施加系統、針織高效燒毛機、飛碟式均勻低給液系統、加濕器、加濕器配件、對中機等產品。我們具有雄厚的技術力量和先進的生產設備,產品質量、性能嚴格按照國際標準,是一支集研發-設計-生產-營銷-服務-管理于一體的企業團隊。我們注重生產的每一個細節,堅持走高品質、高定位的產品路線,確保每一個產品都成為同檔次產品中的佼佼者,我們經過不斷地開拓創新、銳意進取以及堅持完善積極的售后服務,贏得了廣大客戶的信賴和好評!

佛山市順德區德博仕機械設備有限公司的誠信、實力和產品質量獲得業界信賴和認可。歡迎各界朋友蒞臨參觀、指導和業務洽談。

●黃北洋(廣東)

電話:18923210468 0757-27838481

公司地址:佛山市順德區勒流街道新安村發展東路4號

huang beiyang (guangdong)

company address:no.4,fazhan road(e),xin’an village,leliu town,shunde district,foshan city.

●麥國田 (浙南辦)

電話:18098179408

浙江 (浙南)辦地址:紹興市柯橋區華舍街道聚賢花苑33號

mai guotian(southern zhejiang office)

tel:18098179408

zhejiang (southern zhejiang) office address:no.33,juxian garden,huashe sub-district,keqiao district,shaoxing city.

●黃遠遠(浙北辦)

電話:18948985701

浙江 (浙北)辦地址:桐鄉市永興路586號

huang yuanyuan (northern zhejiang office)

tel:18948985701

zhejiang (northern zhejiang) office address:no.586,yongxing road,tongxiang city.

●唐 艷 (福建辦)

電話:18038857418

福建辦地址:石獅市香江路845號

he jianming (fujian office)

tel:18038857418

fujian office address:no.845,xiangjiang road,shishi city