昌邑市昊天紡織機械有限公司

www.ggjmjx.com/company/d4452227/

掃一掃,手機訪問

昌邑市昊天紡織機械有限公司

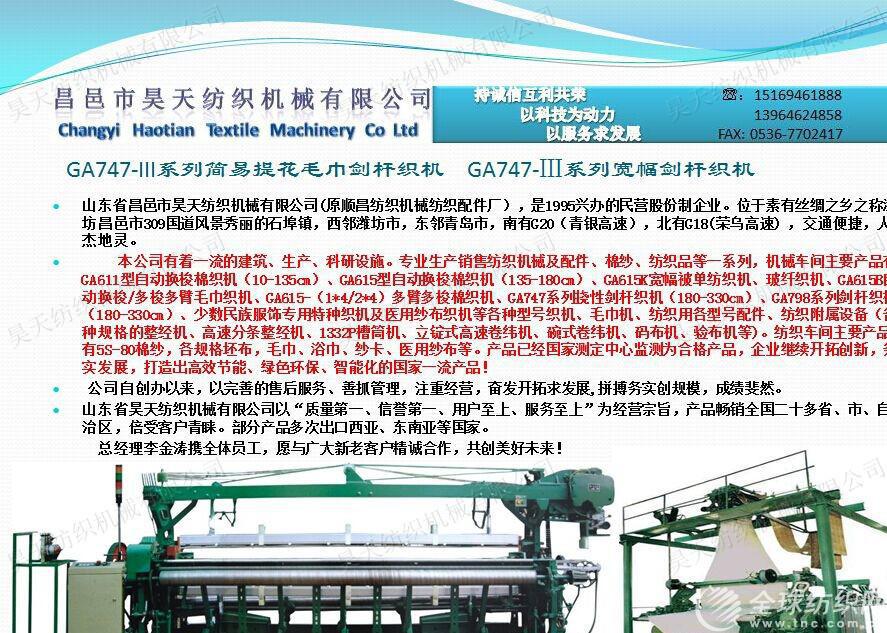

| 品類 | 劍桿織機 | 品牌 | HT |

|---|---|---|---|

| 規格 | GA798-Ⅲ系列毛巾劍桿織機 | 型號 | GA798-Ⅲ系列毛巾劍桿織機 |

產品型號

ga798-ⅲ系列毛巾劍桿織機

1.筘幅寬度:180, 200, 230, 260, 280 (cm).

2.轉 速:設計速度180~230rpm.

3.操作系統:微電腦多功能自動操作控制系統。

4.引緯機構:每分鐘180~230根緯線,通過左右劍帶和劍頭引緯。

5.經盤直徑:標準地經經盤600mm,毛經經盤800mm。

6.卷布軸直徑:300mm (500mm為自選項目)。

7.儲 緯 器:fdp電子儲緯器。

8.驅動控制:額定主電機功率1.5~2.2kw,3相交流電,380v,50hz.

9.打緯機構:曲軸打緯。

10.潤滑系統:多臂機封閉式電子油泵集中加油,整機集中自動加油。

11.電路設計:采用標準模塊化設計,led發光管顯示工作狀態,易檢修,成本低。

12.選緯機構:6~8色電子多臂選緯機構。

13.花型設計:cad電腦設計軟件,通過u盤傳輸文件。

14.織造范圍:細紗:500tex (1.2ne)~5tex (120ne);長絲紗線:10dte(9td )~1650dte(1500td); 紗支:12~32s.

15.開口裝置:14~18片綜框,電子多臂*多24軸自動開口,可匹配大提花機。

16.起毛裝置:采用電腦數控伺服馬達凸輪起毛,3-7緯隨意轉換,無磨損,經久耐用。毛高0~14.5mm.

17.送經機構:采用積極變頻電子數控連續送經系統,反應靈敏,漲力平穩,且有多種送經控制模式。

18.卷取機構:伺服卷取(可設定每一緯緯密,且支持同步變緯密織造。自選項目)

19.布邊形成:機械邊剪,紗羅布邊;伸幅裝置:單排銅刺環輥式。

20.機械傳動:三角帶傳動,電磁離合器制動。

21.停車裝置:停經:單獨電動自動停經裝置;停緯:高靈敏度壓電探測器控制自動停止。4色多功能指示燈顯示停車狀態。

22.電子控制:微電腦多功能自動控制系統附帶存儲卡,大液晶屏界面可用中英文顯示工作狀態,以及機器運行全過程數據,如速度、班/日產量等,調整即時,參數設定和程序制作簡單方便。

23.尺寸/重量:450*250*260cm3, 2.0~2.5mts.

product model

ga798- iii series towel loom

1 reed width: 180, 200, 230, 260, 280 (cm).

2 rpm: design speed 180~230rpm.

3 operating system: microcomputer multifunction automatic operation control system.

4 weft insertion mechanism: 180~230 per minute weft, by about sword belt and sword head weft.

5 the diameter of the disc: standard by the disc 600mm, hair by the disc 800mm.

6 rolling shaft diameter: 300mm (500mm optional).

7: fdp electronic weft weft accumulator.

8 drive control: rated main motor power 1.5~2.2kw, 3 cross flow power, 380v, 50hz.

9 beating up mechanism: crankshaft beating up.

10 lubrication system: multi arm machine closed type electronic pump centralized refueling, the whole set of automatic refueling.

11 circuit design: the use of standard modular design, led light-emitting tube display working state, easy maintenance, low cost.

12 weft selection mechanism: 6~8 color electronic multi arm weft selection mechanism.

13 flower design: cad computer design software, through the u disk transfer file.

14: spinning weaving scope: 500tex (1.2ne) ~5tex (120ne); filament yarn: 10dte (9td) ~1650dte (1500td); count: 12~32s.

15 opening device: 14~18 piece of integrated frame, electronic multi arm up to 24 axes automatic opening, can match the big jacquard machine.

16 raising device: the use of computer numerical control servo motor cam pilling, 3-7 weft free conversion, no wear, durable. mao gao 0~14.5mm.

17 feed through mechanism: the active frequency conversion electronic numerical control continuous feed through the system, the reaction is sensitive, the power is stable, and there are a variety of delivery by the control mode.

18 winding mechanism: servo winding (can be set for each weft density, and support synchronous change weft density weaving. optional items

19: mechanical cutting edge, edge forming leno selvedge tentering device; single row copper thorn ring roller.

20 mechanical transmission: triangular belt drive, electromagnetic clutch brake.

21 parking device: menopause: separate electric automatic stopping device; weft stop: high sensitivity of piezoelectric detector automatic stop control. 4 color multi function indicator display parking status.

22. electronic control: microcomputer multifunctional automatic control system attached to the memory card, large lcd screen interface is available in english display working state, and the machine running the whole process data, such as speed, class / the daily output, the immediate adjustment, parameter setting and program is simple and convenient to be manufactured.

23 size / weight: 450*250*260cm3, 2.0~2.5mts.

招商熱線:400-119-0123

E-mail:qfc1@ctcn.com.cn